Printed Circuit Board Assembly (PCBA)

Magnum provides world class Electronic Manufacturing Services to OEMs and electronic companies. Our professional services include engineering design of electro-mechanical system, material procurement, SMD, through-hole and system assembly from prototyping to volume production. Our comprehensive industry knowledge, strong supplier relationship backed up by a team of engineer and technocrats enables us to exceed customer expectations in meeting their required specification, timelines and budgets.

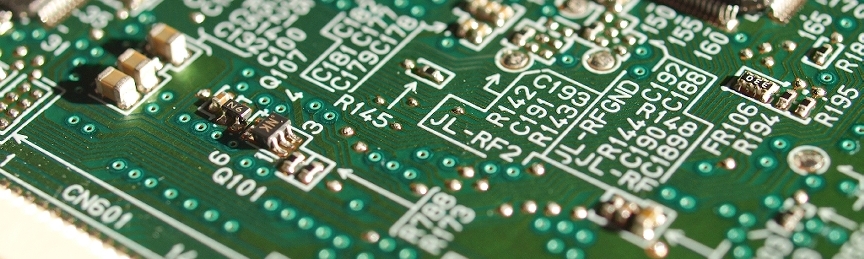

Our Surface Mount Lines are state of the art with accuracy for fine pitch components (0.3mm pitch with vision and laser centering). We handle minimum component size of 0.5mm x 1.0mm and maximum component height of 10mm on our SMT equipment.

PCBA Capabilities

- Low, Mid, High volume manufacturing

- Lead-free manufacturing

- SMT, PTH, mixed technology

- Ultra fine pitch, QFP, BGA, Micro BGA, CBGA

- Automated insertion of PTH (Axial, radial)

- Wave soldering/re-flow soldering

- Aqueous cleaning

- Peripheral process capabilities

- Press-fit back planes & mid planes

- In circuit and functional testing

- Design for eXcellence (DFX) analysis

- Automated conformal coating

- In accordance with IPC-A-610, Class 2

Complete Turnkey Solutions

- Electronic design engineering

- PCB layout design

- PCB fabrication

- Material procurement & Kitting

- Box building (Casing & cable harnessing)

- Functional testing

- Rework & Modification

- Packaging & Logistic services

Testing

- In-circuit testing

- Functional testing

- Special testing as specified by the customers

- Reliability testing such as burn-in and temperate cycle

- Improvement testing such as yield reporting and defect prevention

Quality Management

We follow continuous improvement procedures throughout the manufacturing process to perfect our quality. All working procedures and instructions are well documented and audited periodically. Staff training and development is always on the priority list so that the quality of our people reflects in the quality of the product that we deliver to our customers.

QUALITY CONTROL SYSTEM

- Documentation and document control system

- Engineering Change Order (ECO) and implementation

- Customer complaint analysis

- Corrective actions and implementation

- Statistical process control for continuous improvement

- Non conformance listing, reporting and control

QUALITY STANDARDS

We follow the standards as below in different areas:

- ANSI/ISO/ASQ 9001:2008 and ISO 13485:2003

- ISO10012-1 and ANSI-Z540-1 – Calibration

- IPC-A-610E Class 2,3

- ANSI/ESD S20.20-1999 – ESD Control

Manufacturing Facilities

Certification