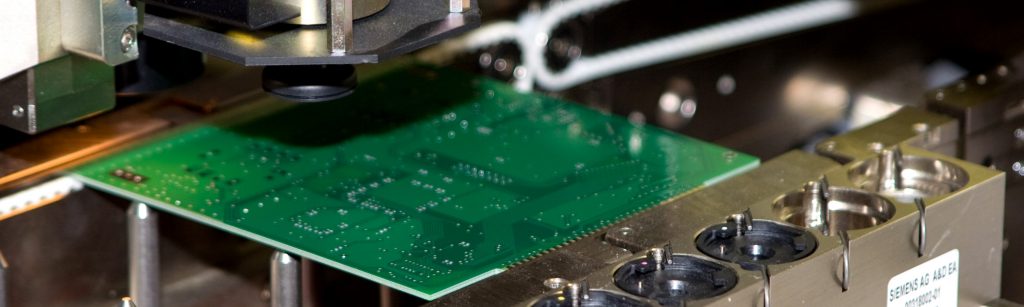

PCB Fabrication

Magnum enjoys over 15 years of reputation as a PCB supplier of high quality standards and competitive pricing. We are qualified and experienced to use standard FR-4, high Tg, halogen free and high speed/ultra low loss materials. Our clientèle extends to medical, gaming, telecommunication and industrial electronics.

Range of PCBs

- Double sided PCBs

- Multilayer up to 16 layers

- RoHS compliant (Tg>170°C) PCBs

- High Density Interconnect PCBs

- Flexible

- Rigid-flex PCBs

Specialization

- Advanced high layer line card

- High performance standard/mid/low loss and Green materials

- Advanced registration system for tight D2M design

- Sequential build up

- N+N, N+M+N structure

- Sequential line card technology for high speed application

- High layer backplane

- Backplane board size up to 40″x20″

- Provider for Telecom

- HDI line card

- Large format System HDI board

Value Added Services through Product Life Cycle

- R&D

- Design for manufacturing

- Material selection

- Panelization

- Optimization

- New Product Introduction (NPI)

- Prototyping

- Pilot testing

- Technical support on issues emerging from prototyping

- Production

- Cost-effective solution

- Reduced lead time

- Price reduction

- Maturity

- High volume

- Improve yield and further cost reduction

PCB Product Overview

Materials

Type of Lamination | Model | Type of Lamination | Model |

Normal Tg | SYL S1141 MICA EG 150T PANASONIC R1755C | High Tg w/ Filler | SYL S1000-2 MICA HR-02 PANASONIC R1755V NELCO N4000-29 |

Middle Tg | SYL S1141KF SYL S1000 MICA LA-02 | Mid/Low Loss | ISOLA FR408, FR408HR NELCO N4000-13, 13SI, 13 EP MITSUBISHI EL-190T HITACHI MCL-HE-679G |

Halogen Free | SYL S1155 R-1566W, WN, V NPGN 150, 170 | Ultra Low Loss | ROGER 4350/4000 PANASONIC MEGTRON 6 |

High Tg | SYL S1170 MICA HR-01 PANASONIC R1755V | PTFE | TACONIC RF-35A2 |

Production Capabilities

Elements | Capability | Elements | Capability |

Max. circuitry width | 564mm | Base copper weight (Inner layer) | 1/3oz – 4oz |

Max. circuitry length | 1021mm | Base copper weight (Outer layer) | 1/4oz – 3oz |

Max. layer count | 20 | Press-fit hole size tolerance | ± 0.05mm |

Max. board thickness | 8mm | Aspect ratio (Line card) | 15:1 |

Max. board thickness tolerance | ± 8% | Aspect ratio (Back panel) | 16:1 |

Routing outline tolerance | ± 10mm | Type of Finishes | |

Impedance ≤ 50Ω | +/- 8% | Single Surface Finishes | ENIG (Autotech CNN/ NPR-8) Electrolytic Nickel Gold Plating Immersion Tin (Stanntech) Immersion Silver (Sterling) OSP (Entek Plus HT), HASL |

Min. inner trace spacing (Line card) | 0.075/0.075mm | Dual Surface Finishes | ENIG (Autotech CNN) + OSP Tab gold (G/F) + I-Silver Tab gold (G/F) + HASL Tab gold (G/F) + OSP |

Production Lead Time

| Lead Time (Days) | |||

| Layer | Standard Protos | Express Protos | Mass Production |

| 2 | 5 | 3 | 10 |

| 4 | 6 | 3 | 14-21 |

| 6 | 7 | 4 | 18-21 |

| 8 | 8 | 5 | 21-24 |

| 10 | 10 | 6 | 23-26 |

| 12 and above | 12 | 6 | From 30 |

*The above lead times excludes transit time to destination

Reliability Testing & Analysis

Testing Equipment:

- SIR tester

- Hi Pot tester

- Wet force balance

- Temp cycling chamber

- SPP testing

- Akrometrix 3D flatness tester

- ATC chamber

- LCR tester

- HAST

- Thermograph

- RoHS tester

- IST tester

- TMA tester

- Ionic contamination chamber

Analysis Equipment:

- IR reflow

- Wave soldering

- SEM & EDX

Industries Served

We serve the following industrial sectors:

- Medical

- Telecommunication

- Gaming

- Industrial electronics

Certification